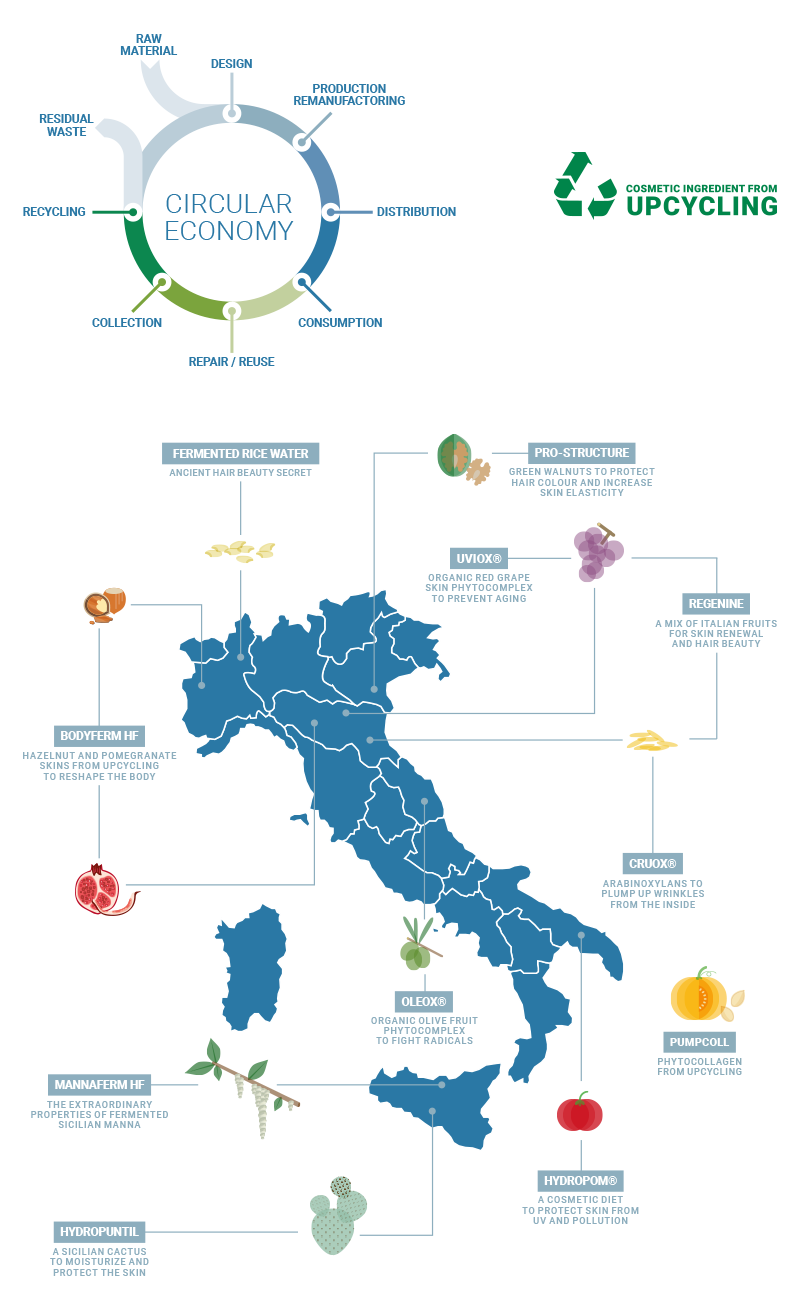

Our Actives from Upcycling

Upcycling is one of the elements of a much wider topic: THE CIRCULAR ECONOMY, a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible. In this way, the life cycle of products is extended reducing wastes as much as possible.

Life Cycle Assessment (LCA) studies the impacts of a product during its existence. The life cycle of a product includes the extraction of the raw materials, manufacturing, packaging, transport, distribution, use and possible reuse, collection, storage, recovery and final disposal of the waste resulting from its use. The goal is to extend the life cycle of materials by reusing them for other purposes before disposal.

Circular economy is not a new concept. Before industrialization, food production was considered to be circular due to its own nature. The traditional farmers’ culture did not tolerate waste, respecting all raw materials, of animal or vegetable origin. Home economics was about subsistence and not about abundance. Everything was considered usable: “Waste not want not”.

In 19th and 20th Century this circular approach was superseded by the linear economic model, which is based on a take-make-consume-throw away pattern. This model relies on large quantities of cheap, easily accessible materials and energy.

Today the circular economy is being re-evaluated in a modern context where the sustainability of resources and processes is again a key point for a fairer development of the society and the protection of the environment.

One of the most relevant factors of this circular approach is to prevent (precycling) or reduce as much as possible waste productions applying different strategies:

UPCYCLING

waste transformation into something of higher quality and value

RECYCLING

waste transformation into something of similar value compared to the starting material (plastic, glass, aluminium recycling)

DOWNCYCLING

waste transformation into something that has less value than the product from which it derives (biogas production).

Phenbiox offers several active ingredients derived by UPCYCLING processes of different co-products and by-products of Italian food productions of excellence.

Functional & eco-friendly packaging

Since 2007 Phenbiox has been packaging its plant extracts in Bag-in-Box rather than the jerrycan. This functional packaging is widely used in the food sector.

The bag-in-box consists of an inner polyethylene bag containing the liquid product, inserted in an outer recyclable corrugated cardboard box. The polyethylene bag is fitted with a tap which makes it possible to very accurately measure out the required amount of product. As the product is extracted, the volume of the bag decreases without any air getting in. This prevents the creation of a headspace, reducing oxidative phenomena and thus the possible loss of product functionality. This system also prevents any microbial contamination of the remaining product.

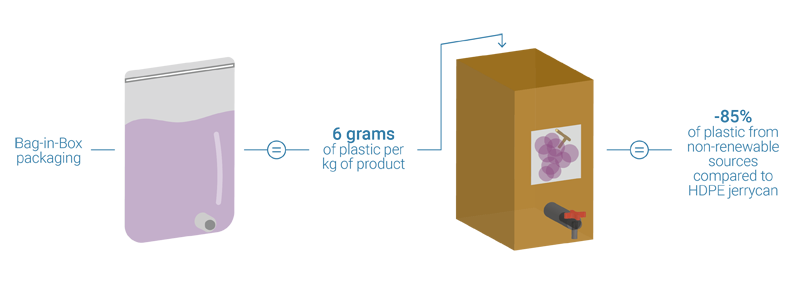

It is possible to calculate the quantity of plastic (obtained from non-renewable oil-based materials) used per kg of extract packed in bag-in-boxes or in conventional jerrycans:

bag-in-box = 0.06 kg / 10 kg = 6 grams of plastic / kg of extract

Jerrycan = 1 kg / 25 kg = 40 grams of plastic / kg of extract.

Using Bag-in-box packaging we can reduce the consumption of plastic material from non-renewable sources by 85% compared to the classic HDPE packaging.

The bag-in-box system used by Phenbiox is produced with 72.5% recycled material helping to conserve natural resources, cut energy consumption and reduce waste sent to landfills and incinerators.